First off, apologies to Joshua Nham, owner of this super clean EM1 that this BBS RS build was destined for, for such a late blog entry. No excuses for my procrastination and tardiness when it comes to writing up articles.

Secondly, I didn't capture as many photos in this project as I usually do so I've been given permission by Allen Yie to share some of his talent. Thanks Allen!

Josh approached me with his 15" BBS RSs in the hopes of getting some rebarrelling done. Josh didn't mess around, knowing exactly what he wanted in terms of lip sizes and finish of the wheels, making my job of setting it all up super easy.

With my advice, Josh had his powdercoater masked up the contact sections of each piece, then done in a solid white.

Assembly was hassle free; if anything, the spikes made the install a tad painful, but it's nothing compared to what Josh has in store for him when he washes the wheels!

Like with all my previous builds, Josh helped out whenever he could throughout it all.

Aftermarket billet hex caps were sourced from the US (check out eBay, seller Aardvarc Racing) as well as red/gold centre caps. Tied together with the white centres and gold bolts, it helped simulate a similar look to the rare "Primadonna" edition of the BBS RS.

Clean beads; let it sit for two days then we parted ways for Josh to have his tyre fitter wrap some 195/45s over them.

The next time I saw them was at JDMyard's EOYM at their new premises located close to home in Smithfield's industrial district. I gotta say, it never gets hold seeing completed wheel builds that I've had a helping hand all fitted up. Can't wait to see proper photos taken of this ;)

Final specs of the wheels were 15x8 ET13 and 15x8.5 ET6, with 2.5" and 3.0" lips respectively.

Thanks again goes to Allen Yie for letting me use his awesome photos!

All other photos can be found on my PBucket.

Welcome to RAW Works. My name is Raymond and I live in the western suburbs of Sydney. This blog will be a portal for me to photo-document the wheels I refurbish and repaint. This is only a side hobby for me so there won't be any crazy custom jobs! My skills have only stretched so far as to using body repair materials, resprays and polishing, so anything that requires welding and unbuckling will be beyond what I can do. I hope to improve on my current skills as I go along, and as a lover of wheels, it's a way for me to express my art side as well as giving life to some tired wheels again.

At the moment, I'm just scouring through eBay for damaged wheels selling for cheap. If you have any wheels you don't need anymore, throw me an email/comment. At the moment I'm just buying sets of wheels to refurb then sell them off. I prefer not to do personal jobs/requests as I don't trust myself with that yet! But that said, pass me an email/comment if you need any help wheel-wise.

My Facebook page is @ http://www.facebook.com/raysalloywheelworks/, please "like" it!

Cheers.

At the moment, I'm just scouring through eBay for damaged wheels selling for cheap. If you have any wheels you don't need anymore, throw me an email/comment. At the moment I'm just buying sets of wheels to refurb then sell them off. I prefer not to do personal jobs/requests as I don't trust myself with that yet! But that said, pass me an email/comment if you need any help wheel-wise.

My Facebook page is @ http://www.facebook.com/raysalloywheelworks/, please "like" it!

Cheers.

Jan 14, 2013

Jan 12, 2013

Project FD, part 2 - assembly and fitting

Last blog entry for this project was back in August. Wheels are now done so I'll just lob two blog entries in one!

Most of you should know by now that the wheels were to be made for Stance Slutz Areis Mo's FD Civic.

As mentioned in part one, I had Areis come over to do a trial fitting to work out suitable widths and offsets. The dynamic camber change from lowering and raising the Civic made it quite tricky to make a definitive measurement but Areis decided to fit some camber arms prior to fitting the BBS RS so if required, we'd have the ability to adjust camber to fit the wheels. The decision to go for a staggered set up was based purely on stance and fitment, nodding towards the current USDM style/trend. 2" lips for the fronts and 3" rears were ordered, and I provided my narrower 6.5" barrels from my beloved RS301 to replace the rears due to 1) the cracked damage and 2) to allow for more camber adjustment for the rears if and when required.

A lot of thought was given to the finish of the centres but for its first revealing, a simple BBS gold was chosen. Areis' spray painter mate Mcgyver was commissioned for the job and he was able to mix a similar colour to the BBS gold going off just from photos. It's a subtle difference but the custom gold mixed is slightly richer and more lustrous than BBS' original gold, something that I really like and would keep in mind for any other future projects.

Special titanium-nickel plated bolts done with a rich gold tint were ordered from Germany and the match was very close.

Like with all my builds, I encourage input from the owners. I think it's important as it provides a sense of fulfillment and self-achievement, something that definitely keeps me going with all these wheel builds and the work I do with my A3. It's a product of your hardwork, your blood, sweat and tears, and not just another item bought off the shelf or ordered online.

... And it makes the job easier for myself hahaha.

When it came time to selecting hex-cap style, there was a lot to consider. There's the conventional half-height and full-height hexes, but with the popularity of BBS RS worldwide, lots of companies have come out with custom hexes, including flat caps (as seen on House of Stance Kennedy's BBS RS on his stanced S14), quarter-height hexes, billet hexes, and also conical caps. But one style I suggested to Areis that I have seen on foreign builds were to run staggered hexes, i.e. run different heights between the pairs of different lip size. I had a few full-height and half-height original BBS hexes in storage that I had refurbished to a mirror polish, and tested it on the wheels, and we were instantly smitten. It's an amazingly subtle look, but one that really boggles those that appreciate these wheels.

Unfortunately we were slowed down by the lip shipment. Turned out one of the lips were actually made for a 16" centre (a step-up lip for some of the rarer, earlier manufactured 17" BBS RS that used 16" centres).

They both use 34 bolts, but the inner diameter as seen above is just millimetres smaller. Fitted perfectly over my BBS RT though ;)

Fast-forward to the New Year and we received the proper lip, and we resumed progress. Just a matter of torquing up the wheels and sealing them.

I don't know how many non-Australian viewers I have here but this current summer has been and still is a scorcher. Fortunately I had A/C fitted in my room so all the bolting up and torquing were done in-house, literally haha.

No dramas in sealing, and with all the practice I've been getting at doing it, my beads are getting cleaner and cleaner :)

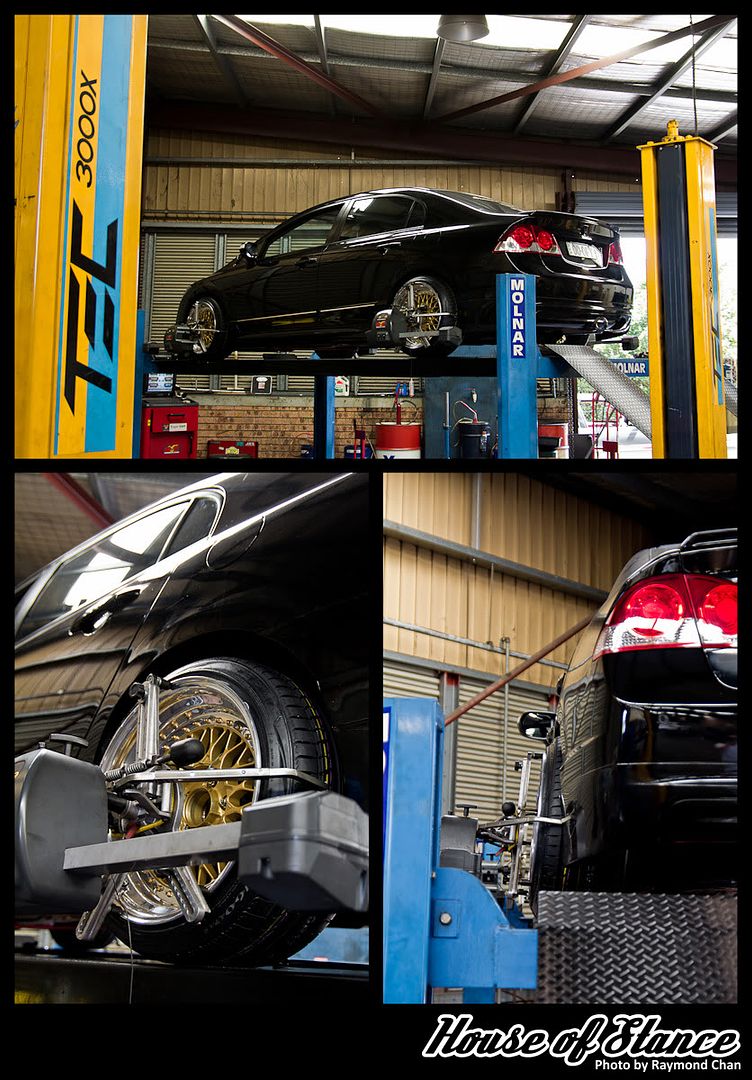

Went back to the team at Merrylands JAX for tyre purchase, fitting and alignment. Areis went for Nexen N6000 in 215/40R17 all around. The final specs of the wheels ended up to be 17x9.5 ET16 and 17x10 ET-3.

First glance we were sorta doubting ourselves...

On the ground, airred out...

So the guard was sitting on the top of the tyre. A bit too Mexican but the aforementioned camber arms will now have their time to shine. Apparently, Areis had the camber arms set to max positive just so he could run some stock steels (as they were hitting the strut!). That gave me a good sigh of relief as I knew right then we'll achieve *that* fitment...

The drive back home was a surreal one for Areis. From start to finish, the build took almost half a year as we ahh-ed and umm-ed about paint/finish themes, bolt-type to use, hex-style and width size and offset. But at the end of it all, we achieved a look and fitment that Areis was happy with so it was all worth it. I'll end this article with photos from an impromptu shoot. Car was still dirty, wheels still had tyre lube, but the fitment's there ;) Enjoy.

More photos can be found on my PBucket.

Most of you should know by now that the wheels were to be made for Stance Slutz Areis Mo's FD Civic.

As mentioned in part one, I had Areis come over to do a trial fitting to work out suitable widths and offsets. The dynamic camber change from lowering and raising the Civic made it quite tricky to make a definitive measurement but Areis decided to fit some camber arms prior to fitting the BBS RS so if required, we'd have the ability to adjust camber to fit the wheels. The decision to go for a staggered set up was based purely on stance and fitment, nodding towards the current USDM style/trend. 2" lips for the fronts and 3" rears were ordered, and I provided my narrower 6.5" barrels from my beloved RS301 to replace the rears due to 1) the cracked damage and 2) to allow for more camber adjustment for the rears if and when required.

A lot of thought was given to the finish of the centres but for its first revealing, a simple BBS gold was chosen. Areis' spray painter mate Mcgyver was commissioned for the job and he was able to mix a similar colour to the BBS gold going off just from photos. It's a subtle difference but the custom gold mixed is slightly richer and more lustrous than BBS' original gold, something that I really like and would keep in mind for any other future projects.

Special titanium-nickel plated bolts done with a rich gold tint were ordered from Germany and the match was very close.

Like with all my builds, I encourage input from the owners. I think it's important as it provides a sense of fulfillment and self-achievement, something that definitely keeps me going with all these wheel builds and the work I do with my A3. It's a product of your hardwork, your blood, sweat and tears, and not just another item bought off the shelf or ordered online.

... And it makes the job easier for myself hahaha.

When it came time to selecting hex-cap style, there was a lot to consider. There's the conventional half-height and full-height hexes, but with the popularity of BBS RS worldwide, lots of companies have come out with custom hexes, including flat caps (as seen on House of Stance Kennedy's BBS RS on his stanced S14), quarter-height hexes, billet hexes, and also conical caps. But one style I suggested to Areis that I have seen on foreign builds were to run staggered hexes, i.e. run different heights between the pairs of different lip size. I had a few full-height and half-height original BBS hexes in storage that I had refurbished to a mirror polish, and tested it on the wheels, and we were instantly smitten. It's an amazingly subtle look, but one that really boggles those that appreciate these wheels.

Unfortunately we were slowed down by the lip shipment. Turned out one of the lips were actually made for a 16" centre (a step-up lip for some of the rarer, earlier manufactured 17" BBS RS that used 16" centres).

They both use 34 bolts, but the inner diameter as seen above is just millimetres smaller. Fitted perfectly over my BBS RT though ;)

Fast-forward to the New Year and we received the proper lip, and we resumed progress. Just a matter of torquing up the wheels and sealing them.

I don't know how many non-Australian viewers I have here but this current summer has been and still is a scorcher. Fortunately I had A/C fitted in my room so all the bolting up and torquing were done in-house, literally haha.

No dramas in sealing, and with all the practice I've been getting at doing it, my beads are getting cleaner and cleaner :)

Went back to the team at Merrylands JAX for tyre purchase, fitting and alignment. Areis went for Nexen N6000 in 215/40R17 all around. The final specs of the wheels ended up to be 17x9.5 ET16 and 17x10 ET-3.

First glance we were sorta doubting ourselves...

On the ground, airred out...

The drive back home was a surreal one for Areis. From start to finish, the build took almost half a year as we ahh-ed and umm-ed about paint/finish themes, bolt-type to use, hex-style and width size and offset. But at the end of it all, we achieved a look and fitment that Areis was happy with so it was all worth it. I'll end this article with photos from an impromptu shoot. Car was still dirty, wheels still had tyre lube, but the fitment's there ;) Enjoy.

More photos can be found on my PBucket.

Subscribe to:

Posts (Atom)