Seems like I'm on a bit of a streak here, one wheel project per year. Fuck I'm lazy.

I finally managed to track down some

BBS RS001. I've always wanted to own a cult set of BBS RS, whether it's these 001, 003 (which I actually have a pair of, but more on that when I find another pair), or 301. They were in

shitty condition though - lips were oxidised and bent (fortunately the inners aren't out of shape), centres were caked with brake dust and some of the stains aren't washable, the centre plates and hexes are chipped and scuffed and the badges are all scratched. These wheels had a very tough life, but hopefully under my ownership they'll be able to somewhat shine again.

I didn't take any pics when I received them as I was out of a camera for a while, but I recently bought one so I'll be documenting the build process with plenty of pics.

The project officially started a few weeks ago when I placed an order for

15x2" lips from Kirsten @ felgenfuchs.de but more on that later. First thing to do was to

disassemble the wheels. 10mm 12pt nuts and 5/16" 12pt bolts. Used an air impact which took no time at all. Knocked off the lips with a couple of hits with a rubber mallet, but the inners didn't want to budge. I ended up keeping them there so they're kinda like a pseudo-BBS RM setup right now. Not the proper way to do things but it'll do.

The bolts were in pretty bad condition, some with bungs in them and some that seem rounded. Don't know if it'll be worth wire brushing all 120 of them down.

I left the wheels aside for a while before coming back to them one sunny weekend to clean them up. I've been spending a minimum of 2 hrs each wheel cleaning them up. Unfortunately, the previous owners seem to have neglected the wheels as there was

a lot of dirt and brake dust build up.

A decent clean produced the silver centres but the in-between parts of the spokes were all

caked with etched brake dust.

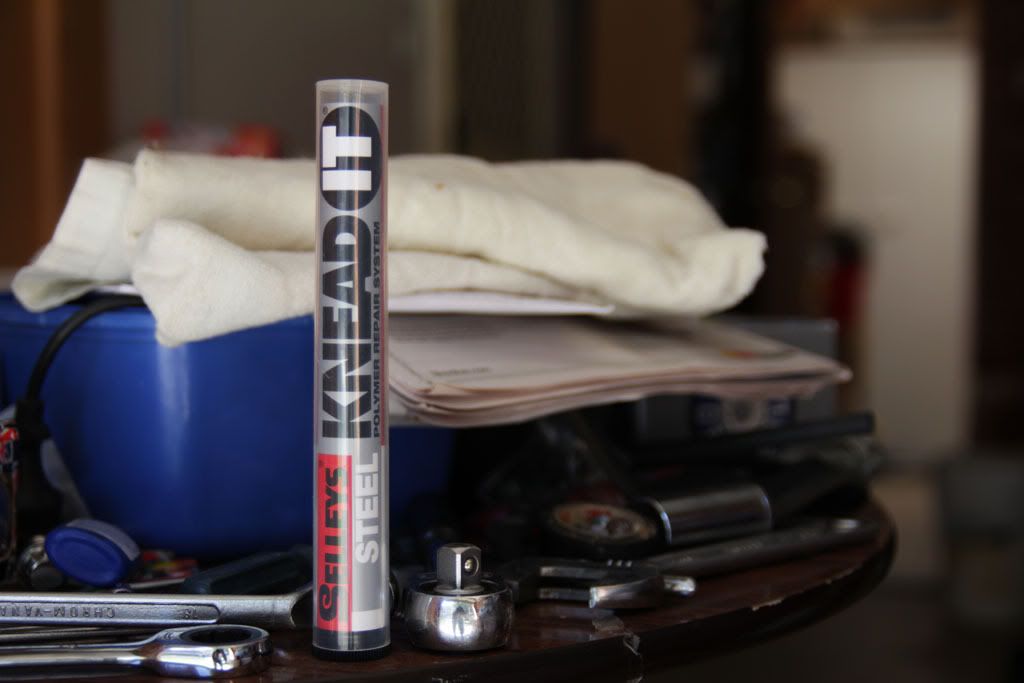

No amount of regular cleaning would remove them, so I decided to use some

Scotchbrite pads on them. I knew the finish won't be glossy silver anymore, but I decided to give it a go. The other plan was to just send them to the powdercoaters and have them sodablasted, but I wanted to keep this build as cost-effective as possible.

Note the oxidation and scoring of the hex. What kind of sick person would neglect their BBSs like this?!

A bit of scrubbing quickly eroded the baked bits.

Not much of the clearcoat/paint was compromised as a result. The outcome was a little surprising actually - the loss of glossiness gave a

satin effect to the silver. The shade became a lot lighter, and in the sun it almost looked white. To be honest, I was quite happy with how they turned out, and I think they look better than the standard BBS silver.

Cleaning the wheels a spoke at a time really allowed me to get up close and notice all the crappy imperfections. Some of the worst were

deep gouges. I really don't know how the previous owner damage them so much, he must've decided to throw some pieces of metal at it while they were rolling or something. There were also parts of the paint that the Scotchbrite couldn't take out.

As of this date, I've cleaned two. Will be cleaning the other two some time this week too.

Now back to the lips. I know that I mentioned I wanted this build to be cost-effective, and the purchase of new lips certainly isn't. Well, I was debating for a while whether to get the lips back to perfect shape again and hand polish them myself, but that would be quite a bit of money and a shitload of time anyway, so I thought why not hit two birds with one stone and fork out a little for some new polished - and wider - lips? A mate was rebuilding his set too so we went on a joint buy to save on shipping. Kirsten was a great bloke to deal with, providing us with a good discount on the lips as well as a sweet shipping deal to boot. I'm currently in the works to buy more stuff from him too, some relating to this build, so I'll be keeping this blog updated when that happens.

Anyway, here they are. It was like

fuckin' Christmas already.

And I couldn't resist a test fit.

Part II should contain more pics of the clean centres. I'm planning to

paint the hexes instead of polishing them as most of them have deep and wide scratch marks. I don't think I'll buy new ones either as it'd just be too expensive. Anyway, black wrinkle paint is the idea at the moment. And also, to tie it all in, I thought some

black chrome bolts would match it up nicely. Will see how it all goes.